MDS Screw Press Sludge Dewatering

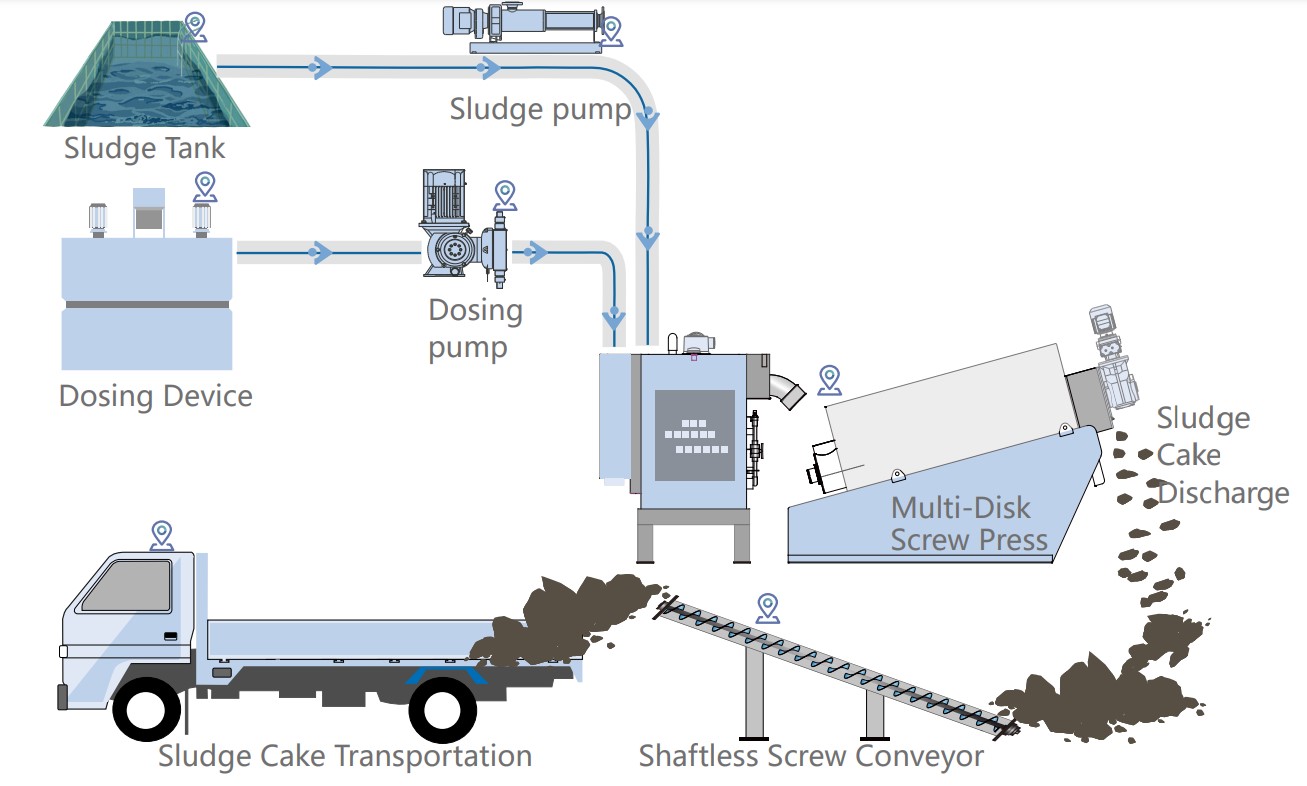

The Multi-Disk Screw press (MDS) is a sludge dewatering machine of solid-liquid separator, which Screw Press Type can realize the Sludge dewatering or Sludge Dehydrator effect.

Application Fields

The MDS is applicable for a wide range of sludge concentration (2000 mg/L – 50000 mg/L), and it’s most suitable for oily sludge treatment plant, and the sludge dewatering unit. It can be widely used in municipal wastewater, food & beverage, slaughtering breeding, printing and dyeing, petrochemical, papermaking, pharmaceutical and other industries that require sludge dewatering. It can also be used in place of a belt press, decanter, or filter press.

Advantages

· Contactless, wear free structure between the disks and spiral, thus extending service life.

· The MDS can treat sludge in aeration tank without setting sludge thickeners. Therefore, reducing capital investment.

· Energy and water saving due to low running speed (2-3 r/min) and no needs for large-scale integrations like rollers. Average power consumption is only 0.1- 0.01kwh/kh-DS (1/8 of belt press and 1/20 of centrifuge). Minimal noise.

· Ubiquitous clogging is avoided due to continuous self-cleaning process.

· Fully automated control with simple and safe operation, programmable based on customised requirement.

· Phosphorus in the sludge can be efficiently captured in the dewatered sludge cake.

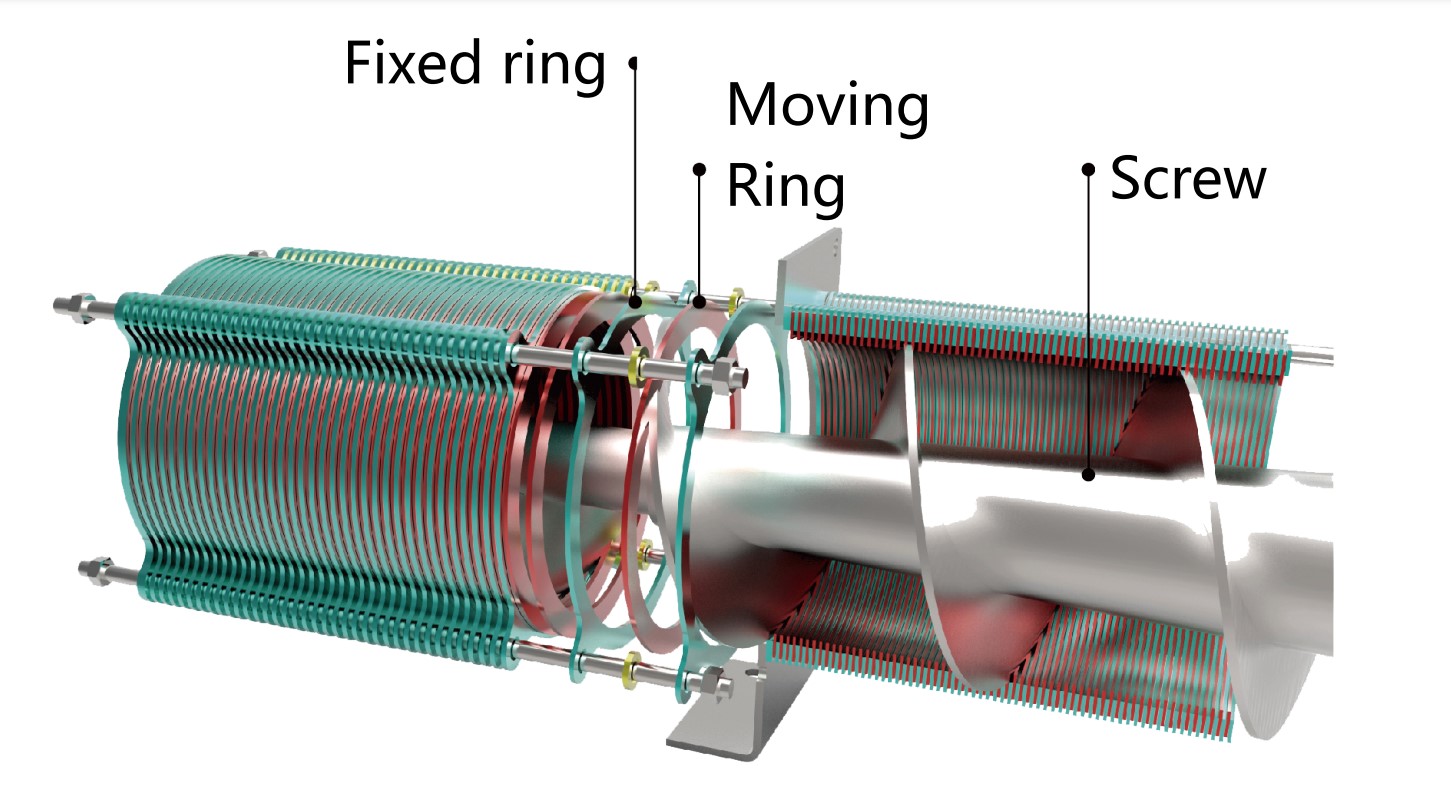

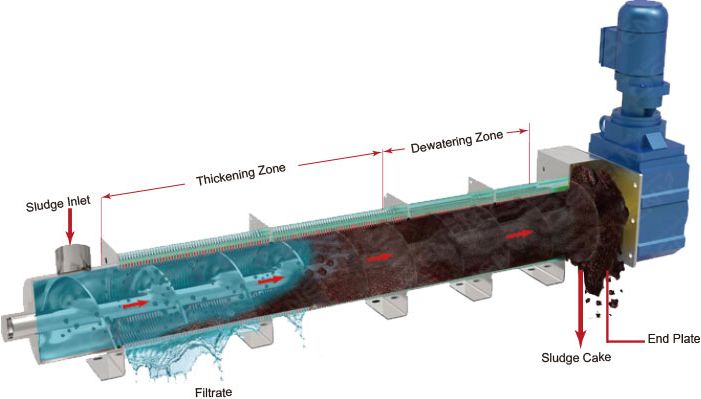

Working Mechanism

The wastewater sludge is thickened and dewatered progressively along with Screw Press sludge dewatering the movement of the free rings, and ending by the rotary filter Screw Press plate. The sludge dewatering equipment special tungsten carbide coating of the inner screw and the sludge dewatering system slow rotation eliminates the friction effect and assure the dewatering screw a long lifespan of the parts. The Sewage Treatment sludge dewatering machine system of filtrate is drained from the gaps between the rings, which differs from the sludge thickening and the sludge dewatering zones. The sludge cake is discharged at the end plate, achieving a minimum solid content of 20%. The MDS Screw Press dehydrator make it a self-cleaning unit due to the friction free movement between the rings.

Product Details

Screw Press Cylinder Check Point

Pre-Sluge Thickening Structure

Technical Paramters

| Model | DS stan capacity (dkagr/dh) | Sludge treatment capacity (m3/h) | ||||||

| Low concentration | High concentration | 2000mg/L | 4000mg/L | 10000mg/L | 20000mg/L | 25000mg/L | 50000mg/L | |

| MDS101 | 3 | 6 | 1.5 | 0.75 | 0.6 | 0.3 | 0.24 | 0.12 |

| MDS131 | 6 | 12 | 3 | 1.5 | 1.2 | 0.6 | 0.48 | 0.24 |

| MDS132 | 12 | 24 | 6 | 3 | 2.4 | 1.2 | 0.96 | 0.48 |

| MDS201 | 12 | 20 | 6 | 3 | 2 | 1 | 0.8 | 0.4 |

| MDS202 | 24 | 40 | 12 | 6 | 4 | 2 | 1.6 | 0.8 |

| MDS301 | 30 | 60 | 15 | 7.5 | 6 | 3 | 2.4 | 1.2 |

| MDS302 | 60 | 120 | 30 | 15 | 12 | 6 | 4.8 | 2.4 |

| MDS303 | 90 | 180 | 45 | 22.5 | 18 | 9 | 7.2 | 3.6 |

| MDS351 | 60 | 120 | 30 | 15 | 12 | 6 | 4.8 | 2.4 |

| MDS352 | 120 | 240 | 60 | 30 | 24 | 12 | 9.6 | 4.8 |

| MDS353 | 180 | 360 | 90 | 45 | 36 | 18 | 14.4 | 7.2 |

| MDS354 | 240 | 480 | 120 | 60 | 48 | 24 | 19.2 | 9.6 |

| MDS401 | 100 | 170 | 50 | 25 | 17 | 8.5 | 6.8 | 3.4 |

| MDS402 | 200 | 340 | 100 | 50 | 34 | 17 | 13.6 | 6.8 |

| MDS403 | 300 | 510 | 150 | 75 | 51 | 25.5 | 20.4 | 10.2 |

| MDS404 | 400 | 680 | 200 | 100 | 68 | 34 | 27.2 | 13.6 |

| Model | Sludge cake | Size(mm) | Net weight | Running weight | Power | Rinsing water | ||

| Outlet height (mm) | L | W | H | (kg) | (kg) | (kw) | (L/h) | |

| MDS101 | 215 | 1860 | 750 | 1080 | 205 | 295 | 0.2 | 24 |

| MDS131 | 250 | 1860 | 750 | 1080 | 205 | 300 | 0.2 | 24 |

| MDS132 | 250 | 1960 | 870 | 1080 | 275 | 425 | 0.3 | 48 |

| MDS201 | 350 | 2440 | 860 | 1380 | 320 | 470 | 0.3 | 32 |

| MDS202 | 350 | 2580 | 977 | 1270 | 470 | 730 | 0.6 | 64 |

| MDS301 | 495 | 3350 | 941 | 1564 | 910 | 1320 | 0.8 | 40 |

| MDS302 | 495 | 3570 | 1260 | 1670 | 1350 | 2130 | 1.2 | 80 |

| MDS303 | 495 | 3830 | 1620 | 1670 | 1820 | 2880 | 1.95 | 120 |

| MDS351 | 585 | 3900 | 1160 | 2190 | 1610 | 2210 | 1.9 | 72 |

| MDS352 | 585 | 4240 | 1550 | 2190 | 2300 | 3400 | 3.75 | 144 |

| MDS353 | 585 | 4460 | 2100 | 2190 | 3350 | 4850 | 6.0 | 216 |

| MDS354 | 585 | 4660 | 2650 | 2190 | 4500 | 6100 | 8.2 | 288 |

| MDS401 | 759 | 4356 | 1170 | 2400 | 2500 | 3400 | 2.25 | 80 |

| MDS402 | 759 | 4900 | 1640 | 2400 | 3480 | 5200 | 4.5 | 160 |

| MDS403 | 759 | 5030 | 2240 | 2400 | 4550 | 7050 | 6.7 | 240 |

| MDS404 | 759 | 5350 | 3240 | 2400 | 6550 | 9660 | 8.2 | 320 |

| Model | Power (kW) | Vulnerable part replacement cycle (h) | Rinsing water pressure | Maintenance frequency | |||

| Screw | Mixer | Total | Screw shaft | Moving ring pressure | |||

| MDS101 | 0.1 | 0.1 | 0.2 | 10000 | 5000 | ||

| MDS131 | 0.1 | 0.1 | 0.2 | 10000 | 5000 | ||

| MDS132 | 0.2 | 0.1 | 0.3 | 10000 | 5000 | ||

| MDS201 | 0.2 | 0.1 | 0.3 | 15000 | 7500 | ||

| MDS202 | 0.4 | 0.2 | 0.6 | 15000 | 7500 | ||

| MDS301 | 0.4 | 0.4 | 0.8 | 30000 | 15000 | 0.1Mpa~0.2Mpa | |

| MDS302 | 0.8 | 0.4 | 1.2 | 30000 | 15000 | (No need for high-pressure flushing device) | |

| MDS303 | 1.2 | 0.75 | 1.95 | 30000 | 15000 | 5 min /day | |

| MDS351 | 1.5 | 0.4 | 1.9 | 30000 | 15000 | ||

| MDS352 | 3.0 | 0.75 | 3.75 | 30000 | 15000 | ||

| MDS353 | 4.5 | 1.5 | 6.0 | 30000 | 15000 | ||

| MDS354 | 6 | 2.2 | 8.2 | 30000 | 15000 | ||

| MDS401 | 1.5 | 0.75 | 2.25 | 30000 | 15000 | ||

| MDS402 | 3 | 1.5 | 4.5 | 30000 | 15000 | ||

| MDS403 | 4.5 | 2.2 | 6.7 | 30000 | 15000 | ||

| MDS404 | 6 | 2.2 | 8.2 | 30000 | 15000 | ||