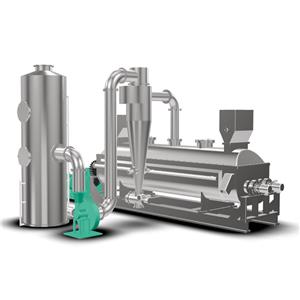

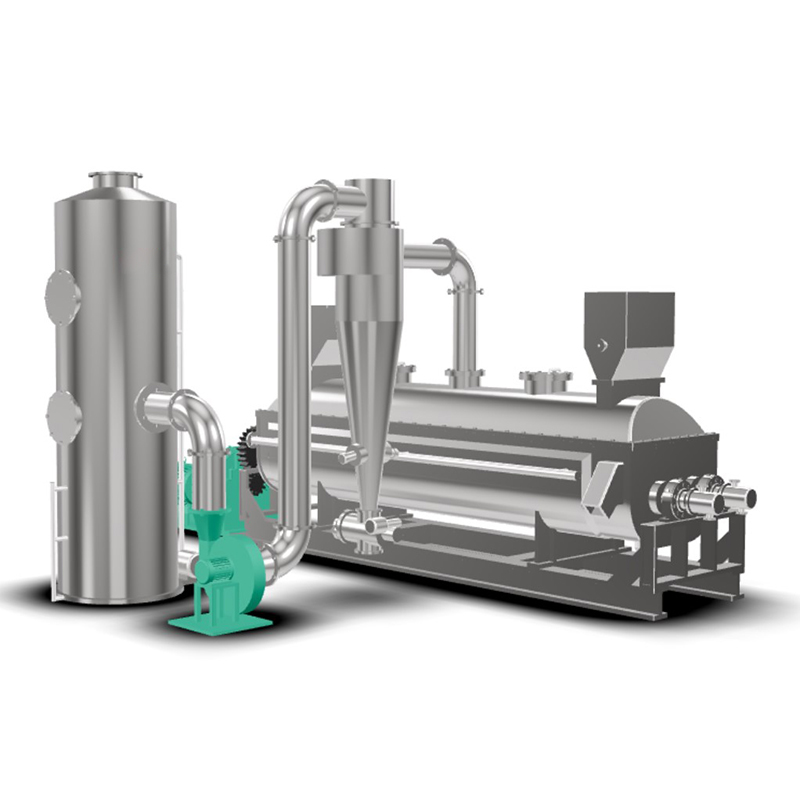

KJG Paddle Dryer

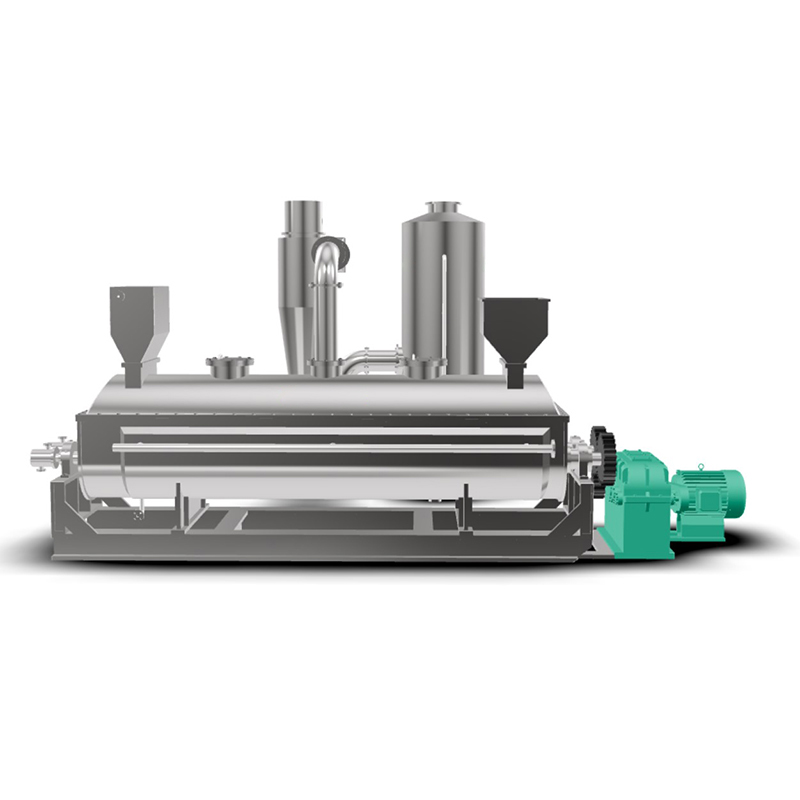

Paddle dryer is a kind of low-speed stirring dryer with stirring paddles set inside the equipment, so that the wet material, under the stirring of paddles, can fully contact with the heat carrier and the hot surface to achieve the purpose of drying, and the structure form is generally horizontal double-axis.

Application Fields

· Petrochemical industry: polyolefin powder, polycarbonate resin, high and low density polyethylene, linear low density polyethylene, polyacetal particles, nylon, etc.

· Chemical industry: Soda ash, NPK compound fertilizer, kaolin, bentonite, white carbon black, carbon black, sodium fluoride oxide, dye, molecular sieve, saponin, etc.

· Environmental protection industry: PTA sludge, electroplating sewage sludge, boiler soot, pharmaceutical factory waste residue, sugar factory waste residue, MSG factory waste residue, coal ash, etc.

· Food industry: starch, cocoa beans, corn kernels, table salt, modified starch, etc.

· Feed industry: soy sauce residue, bone-based feed, lees, food scraps, apple residue, orange peel, soybean meal, chicken bone feed, fish meal, feed additives, biological sludge, etc.

Advantages

· Low Operation Cost

o Easy to operate.

o Requires minimal attention.

o Simple instruments monitor the process.

o High efficiency.

o Low off-gas volume.

· Low Installation Cost

o Designed with compact structure.

o Small off-gas system.

o Vertical shaft removal reduces building size requirements.

· Low Maintenance Cost

o Designed for high torque and low operating speed.

o Simple durable design for easy and low maintenance.

o No internal parts to adjust or maintain.

o No metal-to-metal contact.

o Shafts, pillow block bearings, and drive components are designed for long life under adverse conditions, insuring long term mechanical integrity.

o Robust frame supports split pillow block bearings.

o Grease-purged stuffing boxes. Alternate seal designs are available.

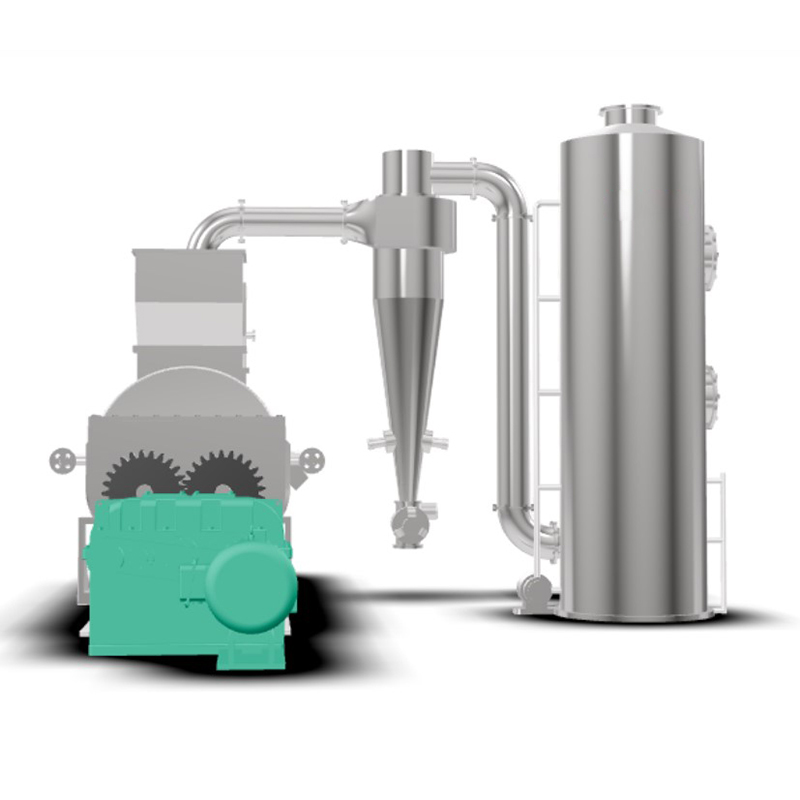

Product Details

Spindle

Cabinet

Technical Parameters

| Item \ Model | KJG3 | KJG9 | KJG13 | KJG18 | KJG29 | KJG41 | KJG52 | KJG68 | KJG81 | KJG95 | KJG110 |

| Heat transferring area (m2) | 3 | 9 | 13 | 18 | 29 | 41 | 52 | 68 | 81 | 95 | 110 |

| Effective volume (m3) | 0.06 | 0.32 | 0.59 | 1.09 | 1.85 | 2.8 | 3.96 | 5.21 | 6.43 | 8.07 | 9.46 |

| Range of rotating speed (rmp) | 15-30 | 10-25 | 10-25 | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 | 5-15 | 5-15 | 5-10 |

| Power (kw) | 2.2 | 4 | 5.5 | 7.5 | 11 | 15 | 30 | 45 | 55 | 75 | 95 |

| Width of vessel (mm) | 306 | 584 | 762 | 940 | 1118 | 1296 | 1476 | 1652 | 1828 | 2032 | 2210 |

| Total width (mm) | 736 | 841 | 1066 | 1320 | 1474 | 1676 | 1854 | 2134 | 1186 | 2438 | 2668 |

| Lenght of vessel (mm) | 1956 | 2820 | 3048 | 3328 | 4114 | 4724 | 5258 | 5842 | 6020 | 6124 | 6122 |

| Total lenght (mm) | 2972 | 4876 | 5486 | 5918 | 6808 | 7570 | 8306 | 9296 | 9678 | 9704 | 9880 |

| Distance of material inlet & outlet (mm) | 1752 | 2540 | 2768 | 3048 | 3810 | 4420 | 4954 | 5384 | 5562 | 5664 | 5664 |

| Height of center (mm) | 380 | 380 | 534 | 610 | 762 | 915 | 1066 | 1220 | 1220 | 1220 | 1220 |

| Total height (mm) | 762 | 838 | 1092 | 1270 | 1524 | 1778 | 2032 | 2362 | 2464 | 2566 | 2668 |

| Steam inlet (inch) | 3/4 | 3/4 | 1 | 1 | 1 | 1 | 5 1/2 | 5 1/2 | 5 1/2 | 5 1/2 | 2 |

| Water outlet (inch) | 3/4 | 3/4 | 1 | 1 | 1 | 1 | 5 1/2 | 5 1/2 | 5 1/2 | 5 1/2 | 2 |