HZP Fibre Disk Filter

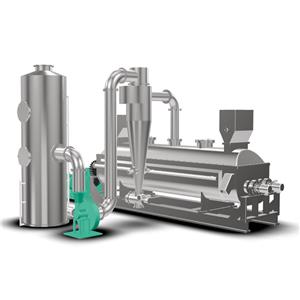

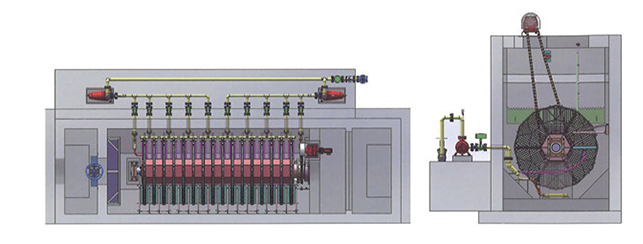

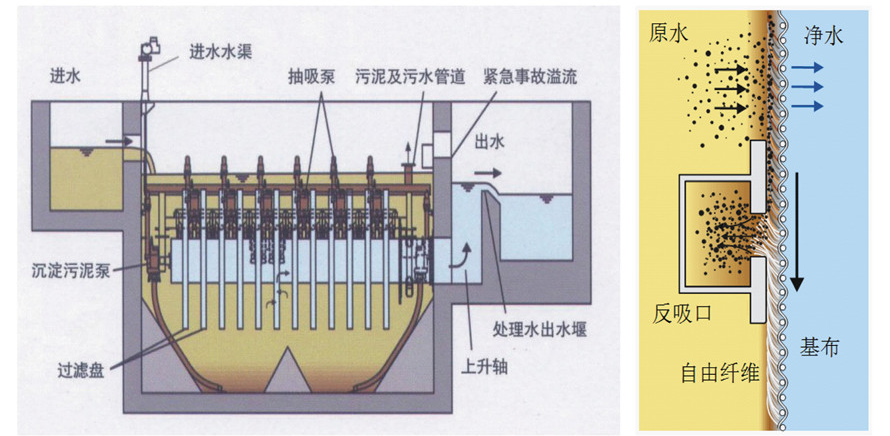

The fully immersed fibre disk filter is composed of a central rotating drum, filter discs, backwash system and supporting electrical control system.

Application Fields

· Upgrading of existing sewage treatment plant: from Class B to Class A discharge standards.

· Recycled water for industrial production: circulating cooling water for steel plants and power plants.

· Reuse of urban miscellaneous water.

· Water used in papermaking, printing and dyeing industries.

· Aquaculture and other water treatment.

Advantages

· Small installed power as raw water passes through the fibre filter cloth under the action of gravity to complete the filtration process. No energy consumption through the process.

· Small area. The fibre disc filter makes full use of the vertical space, and the ancillary equipment is in compact layout, convenient for centralized management and maintenance.

· Small head loss of only 300mm in general setting.

· The system operates continuously under automated control. The filtration process continues even during backwash process.

· Low operating cost. During normal operation, no energy incurred except for activating necessary monitoring components.

· Highly efficient backwash with concentrated energy. Water used is the filtered water from the central pipe.

· Consistent quality of effluent water. Options of fibre filter cloths with precisions up to SS≤5mg/L.

· High impact resistance. Options of fibre filter cloths with water intrusion tolerance up to SS≤50mg/L.

Working Mechanism

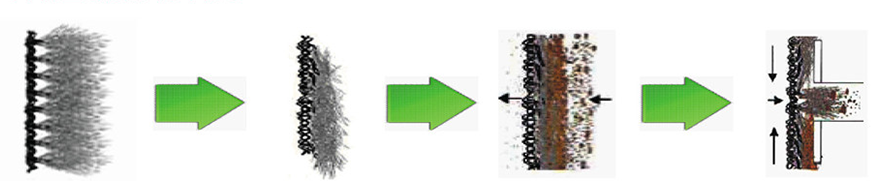

The filter discs are fixed around the central rotating drum and have connecting holes with the central rotating drum. Raw water (sewage) flows into the rotor through the filter cloth on the disc. The filter cloth is a special fibre filter cloth with a filter pore size as small as 10UM. After the raw water is filtered through the filter cloth, the clean water flows into the rotating drum and is discharged from the system through the rotating outlet. As filtration proceeds, the trapped impurities on the outside of the filter cloth continue to increase, the filtration pressure difference increases, and the amount of water passing through the filter cloth decreases. When the impurities accumulate to a certain extent and the filter level reaches the set value, the backwash device starts to operate and backwash out the impurities accumulated on the outside of the filter cloth. After backwash, the sewage impurities are sucked into the sewage pipe and then discharged out of the device. During backwashing, the disc rotates until all filter cloths have been cleaned, then backwashing stops and the static filtration process re-enters. Operate in this cycle.

Product Details

Disc Filter

Filter Cloth

Technical Parameters

| Model | Disc diameter (m) | Single disc filtration area (m2) | Number of discs | Capacity (m3/d) | Installed power (kW) |

| HZP1.2-2 | 1.2 | 2 | 2 | 600 | 0.37+1.5 |

| HZP1.2-4 | 1.2 | 2 | 4 | 1200 | 0.37+1.5 |

| HZP1.2-6 | 1.2 | 2 | 6 | 1800 | 0.37+1.5 |

| HZP1.2-8 | 1.2 | 2 | 8 | 2400 | 0.37+3 |

| HZP2-2 | 2 | 5.8 | 2 | 2000 | 0.55+2.2 |

| HZP2-4 | 2 | 5.8 | 4 | 4000 | 0.55+2.2 |

| HZP2-6 | 2 | 5.8 | 6 | 6000 | 0.75+2.2 |

| HZP2-8 | 2 | 5.8 | 8 | 8000 | 0.75+4.4 |

| HZP2-10 | 2 | 5.8 | 10 | 10000 | 0.75+4.4 |

| HZP2-12 | 2 | 5.8 | 12 | 12000 | 0.75+4.4 |

| HZP2-16 | 2 | 5.8 | 16 | 16000 | 0.75+6.6 |

| HZP2-20 | 2 | 5.8 | 20 | 20000 | 0.75+6.6 |

| HZP3-2 | 3 | 12.6 | 2 | 5000 | 0.75+3.7 |

| HZP3-4 | 3 | 12.6 | 4 | 10000 | 0.75+3.7 |

| HZP3-6 | 3 | 12.6 | 6 | 15000 | 0.75+3.7 |

| HZP3-8 | 3 | 12.6 | 8 | 20000 | 0.75+7.4 |

| HZP3-10 | 3 | 12.6 | 10 | 25000 | 1.1+7.4 |

| HZP3-12 | 3 | 12.6 | 12 | 30000 | 1.1+7.4 |

| HZP3-16 | 3 | 12.6 | 16 | 40000 | 1.1+11.1 |

| HZP3-20 | 3 | 12.6 | 20 | 50000 | 1.1+11.1 |