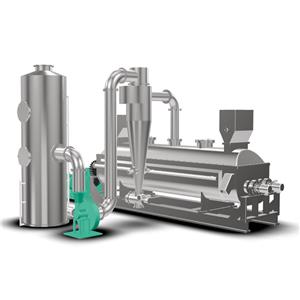

HTJY Automatic Preparation And Dosing Unit

The HTJY Chemical/Polymer preparation and dosing system, is an automatic continuous process, dedicated for the preparation of chemicals used in the water and wastewater treatment.

Description

The chemical dosing unit dissolve dry chemical/polymer powder or the flocculant dosing system can be customized to dilute concentrated solutions. The polymer dosing system is generally made from SS304, and the chemical dosing equipment/polymer feed system from SS316 or HDPE for low pH and special chemicals.

Working Process

1. The chemical dosing system Controlled by the electrical panel, the Powder Dosing system can run in Automatic or manual mode. In Automatic cycle, when the level of the solution is low, and the chemical dosing unit rotary sensor of the powder detect a full hopper, the water solenoid valve is activated and the powder feeding system starts, leading to pre-mixing in a cyclonic movement before entering the first mixing tank.

2. The Flocculant dosing system tank is divided into three compartment: mixing tank, maturation tank, and service tank. Each one has its own mixing device, to assure total dissolution of the chemical powder.

3. The powder dosing system mixers are in continuous stirring action in order to assure the polymer dosing homogenous solution before delivery. The chemical dosing or polymer pumping system is easily connected to the chemical dosing unit, with special protection from dry run. The polymer dosing system provided continuous ready solution.

Technical Parameters

| Model | HTJY-500 | HTJY-1000 | HTJY-2000 | HTJY-3000 | |

| L/M/H (mm) | 1500/930/1620 | 2000/1240/1580 | 2440/1560/1765 | 3000/1820/1915 | |

| Number | Item | ||||

| M-1 | Mixer 1 | 0.75kw | 0.75kw | 0.75kw | 0.75kw |

| M-2 | Mixer 2 | 0.75kw | 0.75kw | 0.75kw | 0.75kw |

| M-3 | Mixer 3 | 0.75kw | 0.75kw | 0.75kw | 0.75kw |

| M-4 | Polymer powder conveyor motor | 0.09kw | 0.09kw | 0.09kw | 0.09kw - 0.12kw |

| N-1 | Water inlet | DN20 threaded union PVC | DN20 threaded union PVC | DN25 threaded union PVC | DN25 threaded union PVC |

| N-2 | Polymer outlet | DN20 threaded union PVC | DN32 threaded union PVC | DN32 threaded union PVC | DN32 threaded union PVC |

| N-3 | Empty outlet | DN20 threaded union PVC | DN32 threaded union PVC | DN32 threaded union PVC | DN32 threaded union PVC |

| 1 | Tank | SUS | SUS | SUS | SUS |

| 2 | Long mixer | SUS | SUS | SUS | SUS |

| 3 | Short mixer | SUS | SUS | SUS | SUS |

| 4 | Polymer powder | SUS | SUS | SUS | SUS |

| 5 | Venturi | SUS | SUS | SUS | SUS |

| 6 | Rotameter | PVC | PVC | PVC | PVC |

| 7 | Y-type filter | PVC | PVC | PVC | PVC |

| 8 | Swoalteenr siud pvpallyve | BC(DN20) | BC(DN20) | BC(DN25) | BC(DN25) |

| 9 | Liquid level gauge | OMRON | OMRON | OMRON | OMRON |

| 10 | Control cabinet | Schneider | Schneider | Schneider | Schneider |

| Solution preparation capacity | 500L/H | 1000L/H | 2000L/H | 3000L/H | |

| Polymer powder dosage (kg/h) | 0.25-3 | 0.5 -5 | 1.5 -8 | 2 -15 | |

| Water flow rate (m3/h) | 0.5 -0.75 | 0.5 -1.5 | 0.5 -3 | 0.5 -5 | |